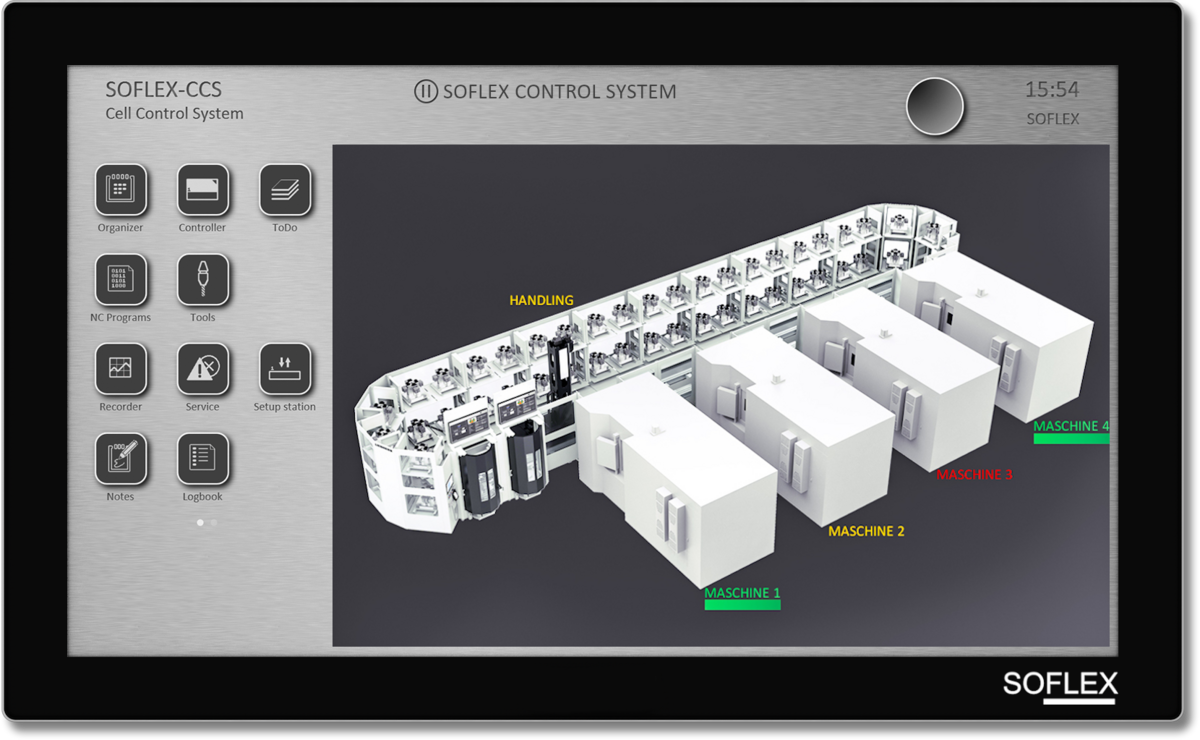

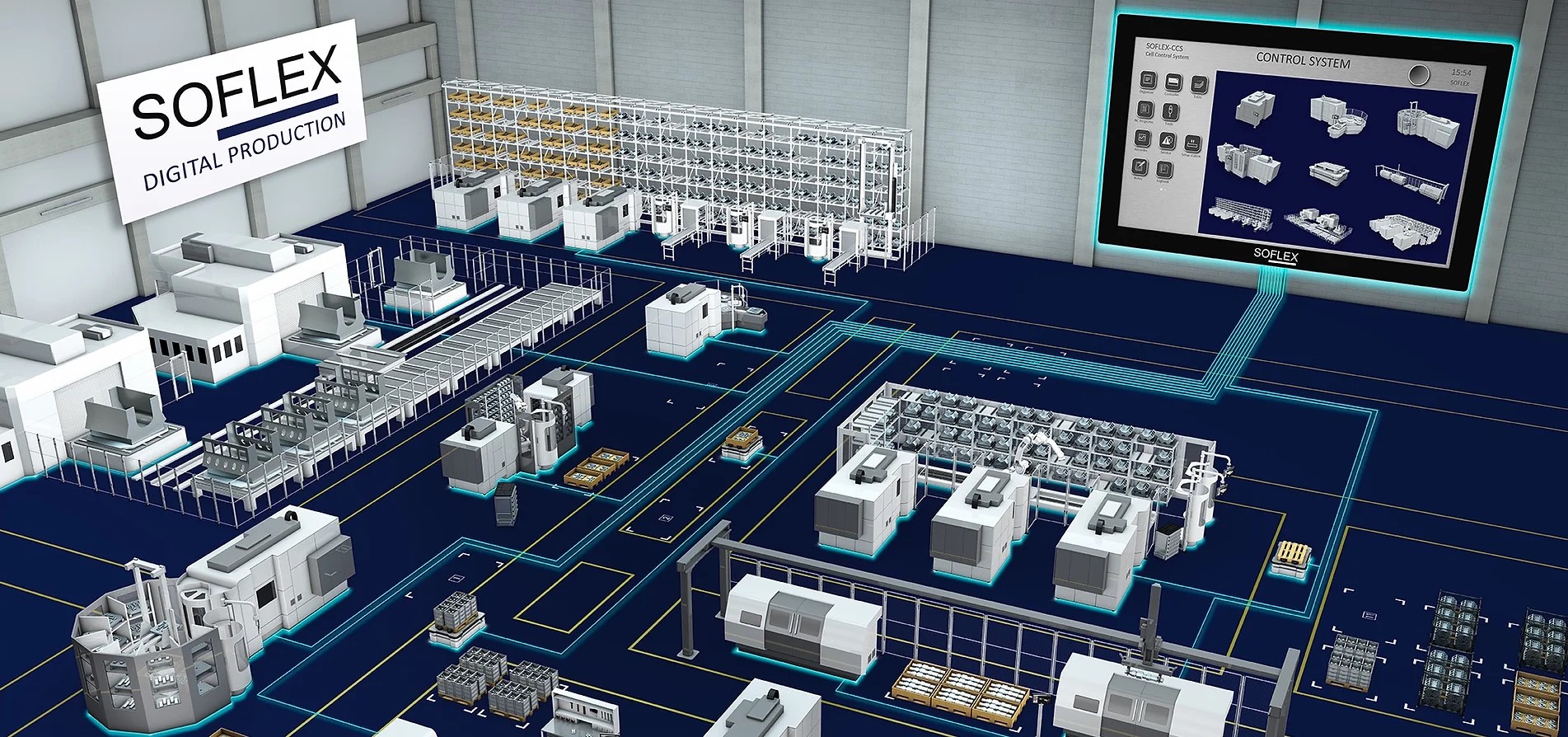

International competition and the shortage of skilled workers also require new strategies and approaches in manufacturing companies. Simple automation or limited digital machine data acquisition is not enough. The smart factory requires a holistic solution that performs organizational tasks quickly and easily, controls the production process on conventional and automated machines and continuously identifies potential for improvement.

SOFLEX solutions realize the "Smart Factory".

SOFLEX products increase the efficiency of your production machines, reduce the use of operating resources, lower your manufacturing costs and compensate for the shortage of skilled workers.

Secure your competitive advantage with this intelligent investment in the future.

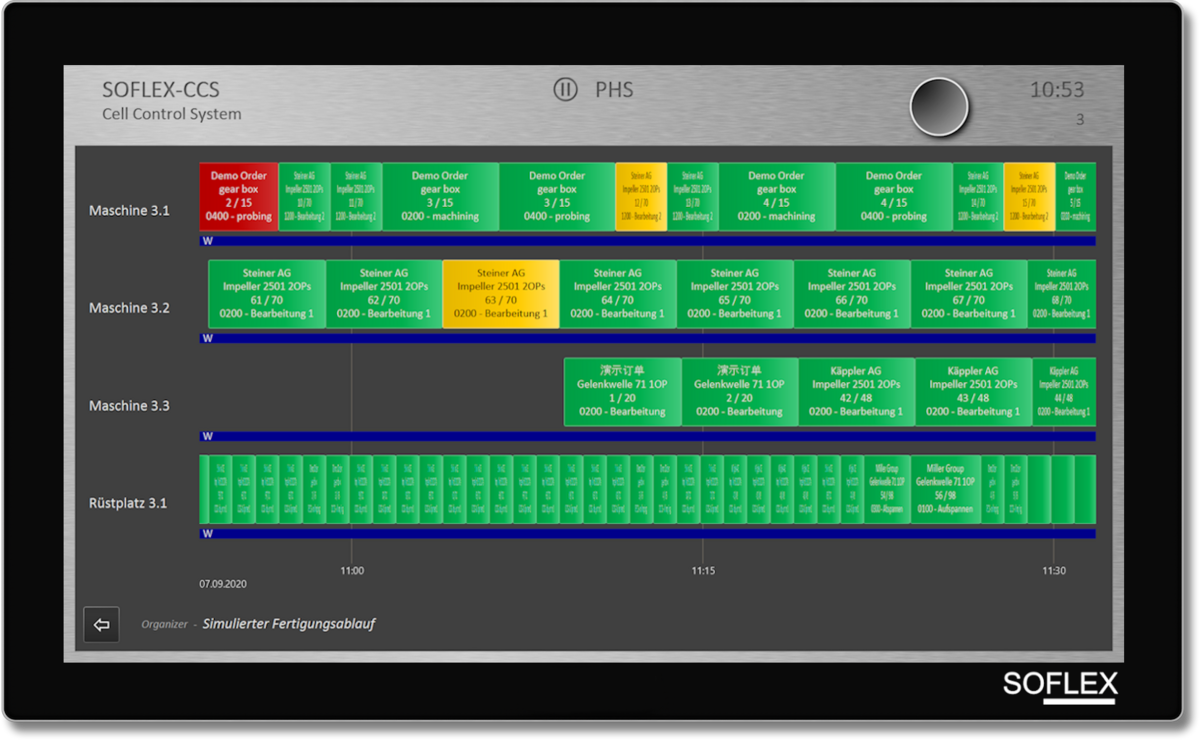

Production orders and planning

Features

- Management of production orders and operation plans

- Rough planning for early detection of capacity gaps or overload

- Detailed planning to optimize the use of operating resources

- Workload simulation for worklist visualization

- Planning of the production orders according to priorities or delivery / start date

- Order progress reports for the ERP system

MANAGEMENT OF MANUFACTURING DATA

Features

- Management of production data such as NC programs, technical drawings, work instructions, test plans, geometrical data, etc.

- Manual import and export functions for all production data

- Automatic data exchange with work preparation systems (PDM, CAD/CAM)

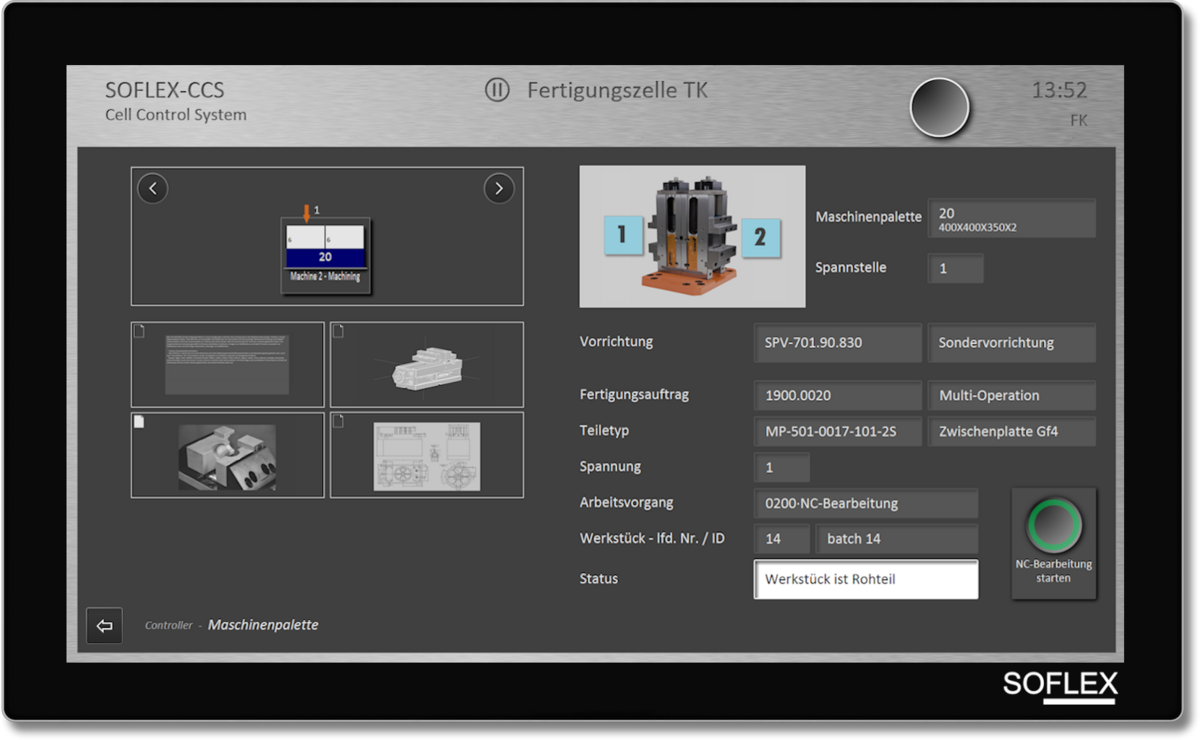

- Visualization of current workpiece status / current work progress

ORGANIZATION OF RESOURCES

Features

- Management of the operating resources: tools, fixtures, measuring equipment, workpiece carriers

- Inventory and storage management

- Calculation of the demand forecast

- Support of picking processes

- Organization of the tool cycle from the presetting area to the machine with automatic data exchange

- Automated and secure process of data provision to the machine (tool, fixture, offset data)

- Service intervals for fixtures

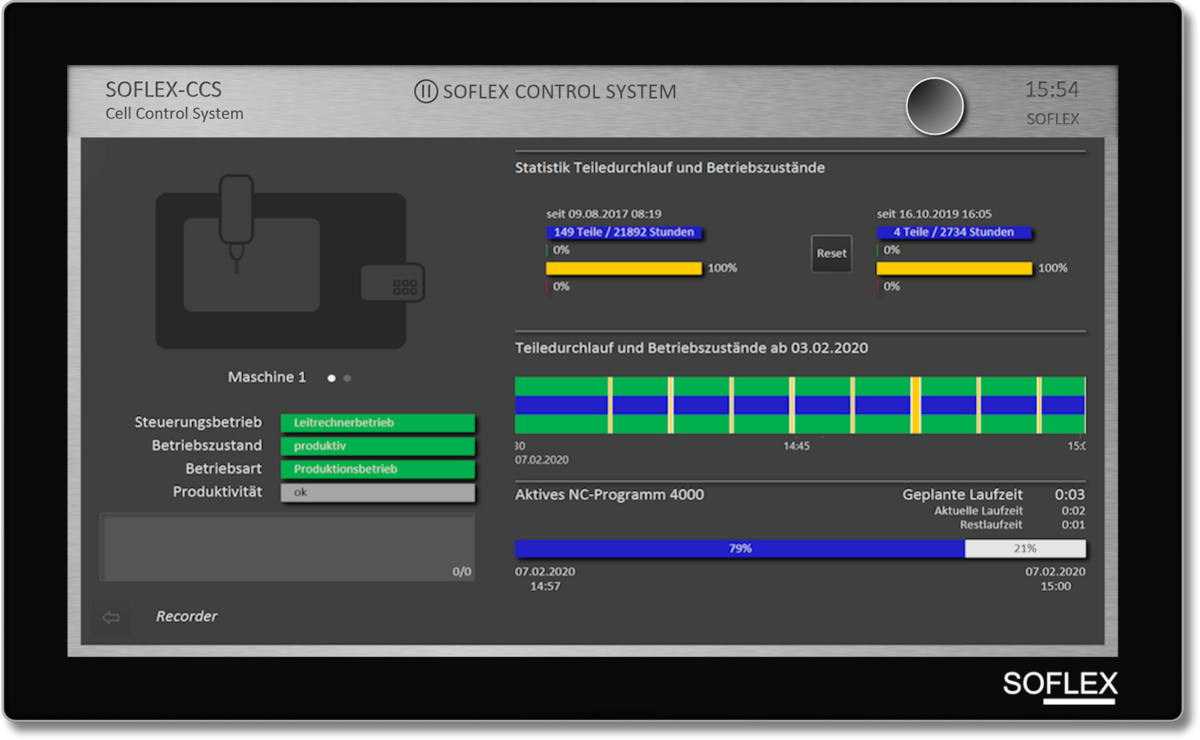

MACHINE & PRODUCTION DATA COLLECTION

Features

- Recording of machine and operating data

- Visualization of machine states and further states of plant components

- Logging and forwarding of alarms and warning messages

- Production monitoring

- Analysis of weak points

- Running time (of NC program, machine, etc.) evaluation

- Part flow documentation

- Analysis regarding availability, degree of utilization, etc.

AUTOMATIC SEQUENCE

Features

- Automated workpiece / raw material feed

- Automated data transfer (production orders, NC programs, tool data etc.) to machines

- Automatic triggering of workpiece processing

- Automatic input/output of resources (workpiece carriers, clamping devices, tools, etc.)

- Automatic operation (bypassing breakdowns)

![[Translate to English:] Neutrales Leitsystem [Translate to English:] SOFLEX Neutrales Leitsystem](/fileadmin/_processed_/f/8/csm_home-pc_7709216de7.png)

![[Translate to English:] Einsatzbereich [Translate to English:] SOFLEX Einsatzbereich](/fileadmin/_processed_/6/1/csm_home-arm_3b05376b36.png)

![[Translate to English:] Smart factory [Translate to English:] SOFLEX Smart factory](/fileadmin/_processed_/c/8/csm_home-factory_e2a9f53444.png)

![[Translate to English:] Betriebsmittelorganisation [Translate to English:] Betriebsmittelorganisation](/fileadmin/_processed_/0/d/csm_Betriebsmittelorganisation_ab6f43298b.png)